What is SLES 70%?

What is SLES 70%?

Headline: SLES 70% Paste: The Definitive Guide to Specs & Performance of a Key Surfactant (CAS 68585-34-2)

Sub-headline: A technical deep dive into Sodium Lauryl Ether Sulfate — from its core chemistry to critical quality parameters that every formulator must know.

Opening Paragraph:

In the world of surfactants, few ingredients are as ubiquitous and indispensable as Sodium Lauryl Ether Sulfate (SLES), identified globally by CAS 68585-34-2. This anionic surfactant is the engineering marvel behind the rich, stable foam in countless personal care and cleaning products. With the global SLES market consistently expanding, driven by demand for effective and versatile cleansing agents, a precise understanding of its technical specifications is not just beneficial—it's essential for innovation and quality assurance. This news feature provides a comprehensive technical profile of SLES, detailing the parameters that define its performance and suitability for diverse industrial applications.

1. Core Product Definition & Chemical Identity

Sodium Lauryl Ether Sulfate (SLES) is not a single molecule but a mixture of related molecules. It is synthesized through a two-step process: first, lauryl alcohol (typically derived from coconut or palm kernel oil) is ethoxylated with ethylene oxide. This intermediate is then sulfated and neutralized to produce the final compound.

The key identifier is its CAS Registry Number: 68585-34-2, which precisely defines this specific chemical mixture of fatty alcohol polyglycol ether sulfates. Its common molecular formula is represented as C<sub>12</sub>H<sub>25</sub>(OCH<sub>2</sub>CH<sub>2</sub>)<sub>n</sub>OSO<sub>3</sub>Na, where 'n' indicates the average number of ethylene oxide (EO) units, most commonly 2 or 3. This EO chain is the critical structural difference between SLES and its cousin, Sodium Lauryl Sulfate (SLS), imparting significantly greater water solubility and milder characteristics.

2. Detailed Technical Parameters & Specifications

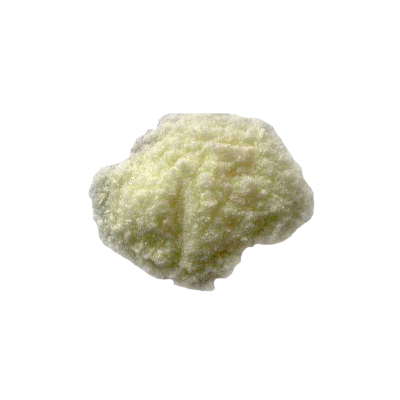

High-quality SLES 70% is most commonly supplied as a viscous paste or gel. The "70%" denotes the high active matter content, making it a concentrated and cost-effective material for manufacturers. Below are the key specifications that define its grade and quality.

Physical & Chemical Specifications (Typical Commercial Grade):

Parameter | Specification | Significance & Impact |

Appearance | Colorless to pale yellow viscous paste/gel | Indicates purity; color can be affected by feedstock and process control. |

Active Matter | 70.0% ± 2.0% | The primary indicator of surfactant strength and dosage calculation. |

pH (1% Solution) | 7.0 - 9.5 | Critical for compatibility with skin, other ingredients, and product stability. |

Unsulfated Matter | ≤ 3.0% | Limits inactive organic by-products; lower values indicate higher process efficiency. |

Sodium Sulfate (Na₂SO₄) | ≤ 1.5% | Controls inorganic salt content; high levels can affect viscosity and clarity. |

1,4-Dioxane Content | ≤ 30 ppm (or lower) | Critical safety parameter. A process by-product that must be minimized to meet global safety standards (e.g., FDA, EU Cosmetics Regulation). |

Viscosity | Variable, often 5,000 - 20,000 cP | Affects handling, pumping, and mixing in production facilities. |

Performance Characteristics:

Foaming Ability: Excellent, producing abundant, stable, and creamy foam, even in hard water.

Detergency & Wetting: Highly effective at removing oils, dirt, and particulates from surfaces and skin/hair.

Emulsification: Good capacity to emulsify oils, aiding in the suspension of soils in rinse-off products.

Biodegradability: Readily biodegradable under standard test conditions, a key environmental consideration.

Compatibility: Generally compatible with other anionic and nonionic surfactants, amphoterics, and most cosmetic ingredients. Direct mixing with cationic agents should be avoided to prevent precipitation.

3. The Critical Role of Ethoxylation (EO Number)

One of the most important yet often overlooked selection criteria is the average number of Ethylene Oxide (EO) units. This is sometimes indicated in product names (e.g., SLES-2, SLES-3).

SLES-2 (approx. 2 EO units): The most common grade, offering an optimal balance of detergency, foaming, mildness, and cost.

SLES-3 (approx. 3 EO units): Exhibits even greater water solubility and mildness. It is often preferred for formulations targeting sensitive skin (e.g., baby shampoos) or where exceptional clarity in final products is required.

Choosing the correct EO grade is fundamental to achieving the desired sensory profile and mildness in the final formulation.

4. Key Differentiator: SLES vs. SLS

A frequent point of inquiry is the difference between SLES (Sodium Lauryl Ether Sulfate) and SLS (Sodium Lauryl Sulfate).

SLS is the non-ethoxylated version. It is an excellent, powerful cleanser and foamer but is known to be more irritating to skin and eyes due to its stronger protein denaturation potential.

SLES, with its inserted ethylene oxide groups, is significantly milder on the skin and eyes while maintaining excellent cleansing and foaming properties. This makes it the surfactant of choice for most modern rinse-off personal care products.

Conclusion

Sodium Lauryl Ether Sulfate (CAS 68585-34-2) is a masterpiece of chemical engineering, a surfactant whose performance is precisely tunable through its ethoxylation degree and tightly controlled by its technical specifications. For R&D chemists and procurement specialists, moving beyond the generic term "SLES" to a detailed understanding of its active matter, impurity profiles, EO value, and dioxane content is the key to unlocking superior product performance, ensuring consumer safety, and navigating complex regulatory landscapes. Mastery of these specs is what separates a standard formulation from an exceptional one.

Keywords for Technical Audiences:

Sodium Laureth Sulfate 70% TDS, CAS 68585-34-2 specification sheet, SLES active matter content, ethylene oxide units in SLES, SLES vs SLS irritation potential, 1-4 dioxane analysis in surfactants, SLES pH stability range, unsulfated matter in anionic surfactants, viscosity of SLES paste, biodegradable anionic surfactant specification.